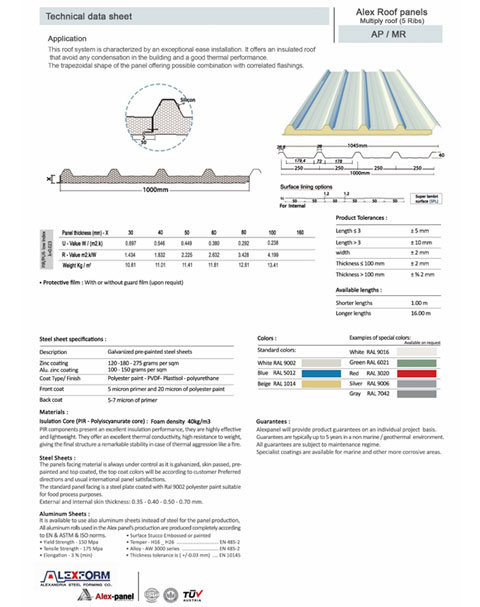

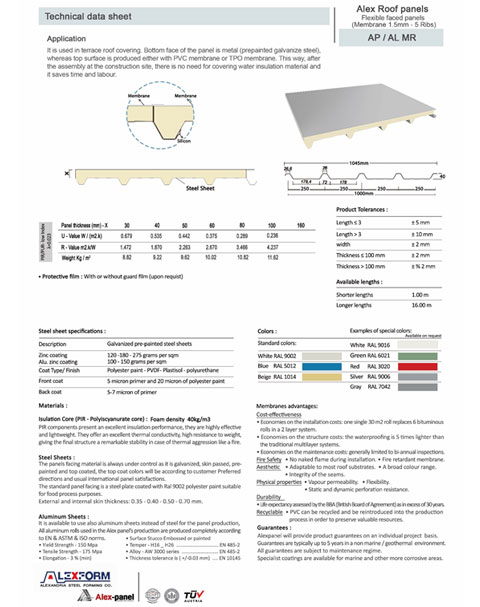

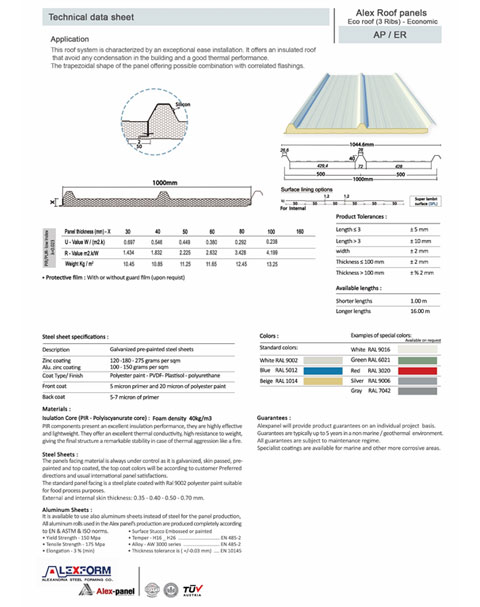

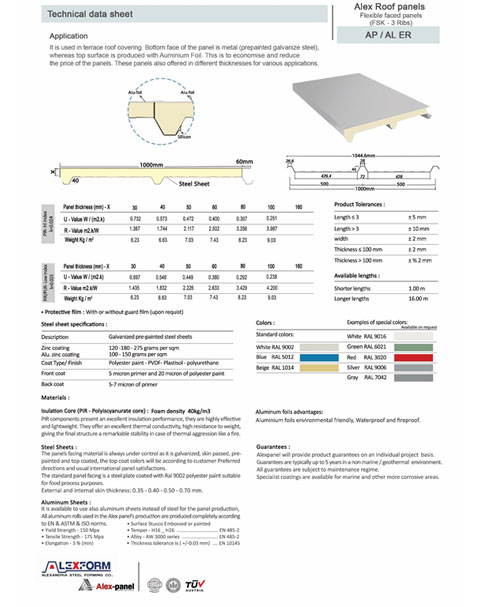

Our sandwich panel consists of an Insulation material (PUR and PIR) that is covered by metal sheets (Steel or Aluminum sheets or flexible faces) which are environmentally friendly following the international standards and specifications.

Quality Control Laboratory : We ensure to maintain our high-quality standards by performing various quality control tests that enable us to discover any kind of minor errors or the slightest deviations from our high set value. Accordingly, our high-value standard is reflected by the quality of our raw materials. One of the main tests we perform is the mechanical test, which includes many forms of testing; bending, shear, tensile and compressive stress tests, in addition to density, visual and dimensional inspections.

Regarding the fire resistance tests, it is for high index PIR sandwich panel to determine the resistance in terms of stability, flame resistance, and thermal insulation. Also, assess the reaction class based on the development of smoke and drips. That what qualifies Alex panel to a great number of certificates.

PIR ( polyisocyanurate ) Core : Products with PIR (polyisocyanurate) nomination correspond with a polyurethane family in which the structure of isocyanate polymer is modified. These structures are consequence of the reaction of molecules of isocyanate with an excess of themselves, giving the final structure a remarkable stability in case of thermal aggression like a fire.

PIR components present an excellent insulation performance, they are highly effective and lightweight. They offer an excellent thermal conductivity, high resistance to weight, combined with versatility of production.

Fire Resistance : Polyisocyanurate (PIR) insulation core provides superior fire-resistance and the special joint (double tongue & groove joint) further protects the core from flame ingress and enables the panel to maintain its structural integrity when exposed to fire.

Panels are classified as fire-resistant when they satisfy certain performance criteria during a real fire situation. Fire resistant panels do not spread fire, contribute to it, spit out burning droplets or emit excessive smoke.

Fire resistant panels preserve their integrity and heat insulation properties for a certain period of time. By successfully meeting these criteria during a fire, fire-resistant panels will provide sufficient time for occupants to safely evacuate the building and implement fire-fighting measures.